The Intake Camshaft from a Honda K24a2 Engine

Luigi Vingo

The City College of New York

The Intake Camshaft from a Honda K24a2 Engine

Fig. 1 Intake camshaft from Honda engine k24a2

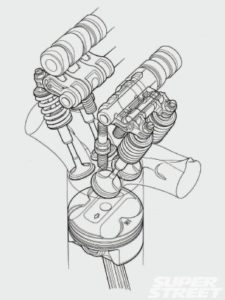

A camshaft is any mechanical device used to transform a reciprocating rotational motion into a periodical straight-line motion (František, Oto, & Danka, 2019) This straight-line motion can be transferred from the cam via an oscillating lever called a rocker arm (Wiki, 2019). The camshaft has been refined and improved over the past two thousand years. Recently over the past two decades Honda has exploited huge advantages with their VTEC system. The VTEC system is used by the intake camshaft of the K24a2, this camshaft is shown above in Fig. 1. VTEC stands for variable valve timing and lift electronic control and is activated by the engine control unit or ECU.

The camshaft is responsible for controlling the components to provide the combustion chamber with air, fuel, and spark in order to create an explosion. Increasing or decreasing one of these components will require doing the same to the other two in order to create an equally efficient explosion. Increasing air, fuel, and spark will also increase the amount of energy which the explosion makes. The energy from the explosion is harnessed via the crankshaft. In order for the entire engine to work together without self-destruction the crankshaft and camshaft must be precisely timed. The camshaft dictates how much power is produced while the crankshaft is responsible for converting the power to be useful.

History

The concepts driving the camshaft were known to the Greeks by 290 CE but were first implemented in mass production by Saint-Sauveur (Black and Riddle, 2016). From 987 to 996 AD he perfected the mechanism using a watermill to produce beer. The cam was widely used to lift a hammer to provide energy to process various resources such as hemp, hides, hops, rice, and wool (Black, 2016). The camshaft appeared again around 300 years later in more modern mechanisms.

Alexander Craig was the first to implement an overhead camshaft design in 1902 (Wiki, 2019). Craig was employed at Maudslay, an engineering firm which had recently began to produce automobiles. Their trademark powerplant was a three-cylinder overhead camshaft engine (WB, 1990), an overhead camshaft engine is any engine where the camshaft is located on top of the combustion chamber. Placing the camshaft on the top of the engine was originally done to make maintenance easier for busses and trucks. Another innovation that was used in these engines are roller rockers which are explained in the components of the camshaft mechanism section (WB, 1990).

Material

A camshafts mechanical property comes from its volume; thus, material choice is an important factor in camshaft manufacturing. There are two main choices when choosing a material for a camshaft, the most common and the choice for the k24a2 camshaft is a chilled iron casting (Wiki, 2019). The other choice available is billet aluminum, but that is very expensive to consider for mass production with little gain in stress resistance. There are various alloys that a camshaft core can be made from, these can be combined with different hardening techniques to get the desire weight and stress resistance for your particular application (Barborak, 2019). Fig. 2 below shows various stages of camshaft wear. The darker areas are a damaged surface, while the silver areas show a healthy cam surface. Poorly chosen cam alloys or inadequate finishing can lead to premature wear labeled b. in Fig. 2.

Fig. 2 Stages of Camshaft Wear

VTEC stands for variable valve timing and lift electronic control and was invented by Ikuo Kajitani. The VTEC system allows for the electronic programing for the engine to vary the amount of air allowed into the combustion chamber. Up until 1989 the system still relied on a single cam for both intake and exhaust valves, Honda debuted their first consumer dual overhead cam (DOHC) engine in 1989, this was done to combat increasing fuel efficiency demands while still providing great performance. The K series engine was introduced in 2001 in a 2.0-liter variation, in 2004 the 2.4-liter version was introduced with the engine code k24a2. These engines are extremely similar, the most important difference is the displacement of the combustion chamber. The 2.4-liter version produces more power because its combustion chamber can hold more air, fuel, and spark.

Components of the Camshaft

Fig. 3 Cam Lobe

The cam lobe is the eccentric circle laid atop a base circle; this is shown above in Fig. 3. The lobe is only the section of the cam above the dotted line in Fig. 3. The top of the cam lobe is also called the nose of the cam, this is the maximum distance that the valve will lift to allow air into the combustion chamber. The valve remains closed during the circular half of the cam called the base circle. Before the nose the valve is opening and the valve begins to close immediately after the nose becoming fully shut again when reproaching the base circle. The combustion takes place during the time the cam in in the base circle for a given cylinder. There are three main characteristics to the overall shape of the Cam lobe called the cam profile. The three characteristics are the base circle, the effective parts, and the leading and finishing parts. The base circle is outlined above and ends at the dotted lines, the sides of the lobe are considered the effective part where the valves are opening and closing (Barborak, Rakusova, Snahnian, 2015). Lift is the difference between the radius of the base circle and the height of the eccentric circle (Coon, 2009). The k24a2 takes advantage of having the ability to change its lift to suit its need for a particular output or engine speed, this ability to switch cam lobe sizes is called VTEC. The difference between the lobes can be viewed below in Fig. 4. The larger VTEC lobe is directly behind the normal operation lobe.

Fig. 4 High and Low Cam Lobe

Center lines, Duration and Overlap.

Duration is the amount of time the valve is not in its closed position. The duration is given in degrees, although this number must be multiplied by two because the crankshaft will spin two times for every one time the camshaft spins (Coon, 2009). It is much easier to time the engine properly using the crankshaft instead of the camshaft due to it being larger in diameter. In order to properly time the opening of the valves each camshaft has a centerline value. The relation of the camshaft and crankshaft are permanently fixed, it is important that the eccentric circle is in the correct position in relation to the crankshaft. In order to provide air at the correct moment for compression and ultimately combustion. This value is given in 0 thru 360 degrees, these degrees are measured from the moment the piston is at its highest point on the crankshaft. While the duration is a fixed value that each camshaft has, the k24a2 has variable valve timing to change when the valve begins to open in relation to where the crankshaft is.

Components of Camshaft mechanism

Rocker Arm

Fig. 5 K24a2 rocker arm

The rocker arm is a lever which oscillates as the cam spins. The cam provides rotating motion, this forces the flat side which is in contact with the camshaft of the rocker up simultaneously forcing the round side which is in contact with the valve down, providing linear motion to open the valve. For the k24a2 this is how the intake cam can take advantage of the bigger cam lobes providing more lift which leads to more air. The ECU of the car checks temperature and throttle sensors before using engine oil pressure to lock the rocker arm allowing it to follow the larger cam lobe. The switch to the larger lobe allows more air into the combustion chamber resulting in more power and increased efficiency. The k24a2 uses a roller rocker type rocker arm pictured above in Fig. 5. The roller rockers advantage is that the surface area that comes into contact is larger than having a flat tappet constantly being in contact at the same point. This drastically increases longevity of the both the rocker and camshaft while simultaneously increasing efficiency through reducing friction (Wiki, 2019). The rollers on the k24a2 are enormous compared to what is found inside most engines. This is most likely due to the k24a2 having high output per liter resulting in more stress resistance needed when manufacturing.

Journal

Fig. 6 Journals holding camshaft assembly (journals circled in red)

The journal is fixed in the engine and serves as a frame to hold the camshaft in place (Barborak, 2019). The journals are mostly hollow pieces, inside each journal motor oil flows through to lubricate the contact point at which the roller rocker touches the camshaft. Shown above in Fig. 6 is the entire cam mechanism assembly, this image shows how the journal holds the other components in place. Proper lubrication is vital in keeping the contact points within an engine within safe operating temperatures. The k24a2 takes advantage of the natural compact design of a four-cylinder engine to ensure the camshaft is never starved for lubricant.

Timing Chain

The main driving force of the camshaft is supplied from the crankshaft via the timing chain. As stated above the crankshaft spins twice for every one revolution of the camshaft. The relationship between the camshaft and crankshaft is not only important in increasing efficiency. The k24a2 is an interference engine, this means that the valve and the piston do share the same space, just not at the same time. If the synchronization of the camshaft and crankshaft is off by the smallest margin this can and will ultimately lead to a catastrophic failure. VVT stands for variable valve timing, it alters the moment when the valve lift event occurs (Wiki, 2019). The shift in timing is referred to as advancing or retarding the engine timing. Advancement can result in more low-end torque, while retarding the timing will give more high-end power. Simultaneously the advancement will bring the valve and piston closer together while retarding the timing will give more clearance (Lutani, 2016).

Honda K24a2

The camshaft on the k24a2 takes advantage of many different advances in camshaft design. It starts its life as a specific blend alloy of chromium, iron, molybdenum, and silicone. The core is then shaped into a very specific shape designed for this particular engine. A major mechanical choice in the design of the k24a2 cam mechanism was the implementing of a roller rocker to reduce friction allowing for higher engine speeds and more power. The camshaft itself is designed with 2 different cam lobes but the VTEC system has taken full advantage of the onboard computer, monitoring throttle and system temperatures. The ECU makes it possible to closely monitor the engine and anticipate needed air intake. The VTEC changes how much lift is supplied, another system that the on-board computer uses to supply air precisely is the VVT system. VVT stands for variable valve timing, this system ensures the crankshaft and camshaft stay precisely timed regardless of which cam lobe the engine is operating on (Wiki, 2019).

After years of use and three different designs the k24a2 is the end of a long line of naturally aspirated four-cylinder Honda engines. The success of this engine is due to having two cam lobes on the intake cam, giving the 2.4-liters of combustion maximum fuel economy while also having the performance benefit of a higher valve lift from the larger cam lobe. The end result of the design of the k24a2 camshaft is a system that can take full advantage of all 2.4 liters found within the combustion chambers, this is referred to as volumetric efficiency. Volumetric efficiency of an engine greatly depends on the camshaft and the timing of the valve openings. The k24a2 has a high volumetric efficiency it can ingest more air, with more air more fuel can be added per spark, burning more fuel leads to more power (Ferrera, 2016). The k24a2s’ camshaft design gives a product that supplies air to the k24a2 engine resulting in an engine that is cost efficient, fuel efficient, and powerful. This is all given with extreme durability and reliability, it is extremely difficult to outperform the longevity of this engine. I attribute this engines durability to the availability of two separate cam lobes, with these the engine can have a high max power output but only give minimal fuel when low amounts of power are needed. The ability to closely monitor and provide enough air intake allows this engine to run strong and last. Below in Fig. 7 the combustion chamber is pictured in operating alignment with the camshaft and its components.

Fig. 7 Controlling air flow

References

[Camshaft Lobe]. Retrieved April 26, 2019, from https://help.summitracing.com/app/answers/detail/a_id/4699/~/camshaft-lift

[Camshaft Mechanism]. Retrieved April 26, 2019, from http://www.superstreetonline.com/how-to/engine/1306-how-vtec-ivtec-works/

[Camshaft wear]. Retrieved April 26, 2019, from http://www.v8wizard.com/Camshaft_wear.php

Coon, S. (2009, February 13). Camshafts: What s All the Fuss About? Retrieved from http://docplayer.net/43607336-Camshafts-what-s-all-the-fuss-about.html. [Accessed 23 Apr. 2019].

En.wikipedia.org. (2019). Rocker arm. Available at: https://en.wikipedia.org/wiki/Rocker_arm [Accessed 27 Mar. 2019].

En.wikipedia.org. (2019). Variable valve timing. Available at: https://en.wikipedia.org/wiki/Variable_valve_timing [Accessed 27 Mar. 2019].

En.wikipedia.org. (2019). VTEC. Available at: https://en.wikipedia.org/wiki/VTEC [Accessed 27 Mar. 2019].

En.wikipedia.org. (2019). Camshaft. Available at: https://en.wikipedia.org/wiki/Camshaft [Accessed 27 Mar. 2019].

František, S., Oto, B., & Danka, R. (n.d.). Materials used in a construction of a camshaft mechanism. Retrieved April 01, 2019, from http://www.inase.org/library/2015/books/bypaper/MMMCE/MMMCE-12.pdf. [Accessed 23 Apr. 2019].

[K24a2 camshaft]. Retrieved April 26, 2019, from https://www.heeltoeauto.com/honda-genuine-cam-usdm-2006-08-cl9-tsx-intake-camshaft-rbb.html

[K24 Rocker arm]. Retrieved April 26, 2019, from https://www.ebay.com/itm/OEM-Honda-Acura-Rocker-Arm-Assembly-K20-K24-Civic-SI-RSX-TSX-/183522991052

Lunatipower.com. (2019). Cam Profile Terms – Lunati Power. [online] Available at: https://www.lunatipower.com/Tech/Cams/CamProfileTerms.aspx [Accessed 27 Mar. 2019].

Michael Ferrara, (2019). Available at: https://dsportmag.com/the-tech/camshaft-tech-101/ [Accessed 27 Mar. 2019].

[VTEC lobe]. Retrieved April 26, 2019, from https://honda-tech.com/forums/acura-tsx-46/k20a-vs-k24a2-camshafts-2837189

- “FORGOTTEN MAKES: No.88-The Maudslay | Motor Sport Magazine Archive.” Motor Sport Magazine, 27 Nov. 2014, www.motorsportmagazine.com/archive/article/january-1990/42/forgotten-makesno88-maudslay. [Accessed 23 Apr. 2019]. Originally published Jan. 1990.

Recent Comments